OCG-Wind

Sustainable offshore solutions

The OCG-Wind is a Floating Offshore Wind Turbine (FOWT), which has been developed with two following key drivers:

– A low Levelized Cost of Electricity (LCOE) which is directly linked to its light weight and a minimized Capital Expenditure (CAPEX).

– An availability for power production close to 100%.

– Industrialization and large-scale deployment, enabled by full modularity with individual components that can be fabricated and transported efficiently and assembled near the wind farm site.

About

OCG-Wind

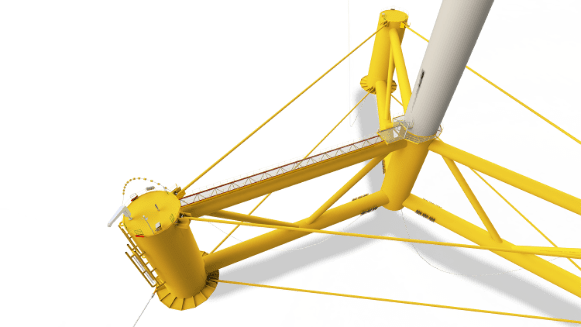

The OCG-Wind is a four-column semi-submersible floating platform specifically designed for large wind turbines. The lightweight modular hull can be fabricated and assembled in a fully industrial manner, maximizing the flexibility to use local and global supply chains.

The centrally located turbine minimizes constrains brought by large wind turbines: The turbine weight is shared among all columns, which reduces the water depth requirement at quayside, and minimizes the need for ballasting operations to trim the platform between lifts.

Additionally, the destabilizing yaw moment is considerably reduced. This decreases the potential for yaw oscillations leading to improved turbine performance and reduced requirements on the station-keeping system. Turbine assembly can be performed with existing cranes suitable to handle the weight and height of modern commercial-size offshore wind turbines.

About

STRUCTURE

The OCG-Wind is made of steel, which is much lighter than concrete hulls and can easily be recycled at the end of its design life. This eases final assembly and the use of a crane to perform the load-out operation and enables efficient fabrication using steel pipe factories. The three-legged mooring system is simpler to install and commission due to the low wave forces on the structure.

The OCG-Wind floater is a tensegrity structure, as tendons interconnect each pair of outside columns near their top and bottom ends.

By fabricating component globally and assembling them close to the project site, a broader supply chain can be targeted, and the fully commissioned turbines can be installed offshore at the rate of at least one unit per week, a key requirement for the economic viability of commercial-scale floating offshore wind projects.

Fabricated and assembled in a fully industrial manner, maximizes flexibility to use local and global supply chain

About

Preferred EPCI services provider

Ocergy and Archer Wind have established a strong cooperation for EPCI services.

This partnership between Archer Wind and Ocergy integrates one of the most promising FOW technologies in the world with the strong EPCI leadership to develop a fully industrialized supply chain to serve wind farm developments worldwide.

Archer Wind is building a robust supply chain to deliver offshore wind projects and has established robust working relationships with key partners in the industry. OCG-Wind projects benefits from this strong One Team approach. Qualification of key component suppliers, fabricators, assembly yards and T&I companies is ongoing.

Archer Wind is certified by DNV for both quality (ISO 9001) and environmental (ISO 14001) management systems.

SEND US AN EMAIL

Better yet, reach out to us

We are very happy to communicate about the project and discuss its multiple facets